infrastructure

Lakshmi Moulds & Dies

State-of-the-Art Facilities

Lakshmi Moulds and Dies operates two advanced manufacturing units in Hosur, strategically located to serve OEMs and Tier 1 customers efficiently. Our well-equipped facilities ensure precision, reliability, and scalability in plastic injection molding and mould manufacturing.

Lakshmi Moulds & Dies

State-of-the-Art Facilities

Lakshmi Moulds and Dies operates two advanced manufacturing units in Hosur, strategically located to serve OEMs and Tier 1 customers efficiently. Our well-equipped facilities ensure precision, reliability, and scalability in plastic injection molding and mould manufacturing.

Lakshmi Moulds & Dies

Advanced Technology & Equipment

We leverage cutting-edge machinery and automation in our production processes. Our facilities are equipped with:

- High-precision injection molding machines

- CNC and EDM machines for die manufacturing

- Automated quality inspection systems

- In-house toolroom for maintenance and customization

Machinery Type & Category

Arburg

All rounder 550 – 50 Ton Capacity

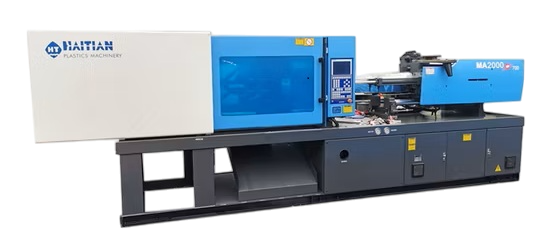

Haitian

HTF – 80 Ton

HT – 120 Ton

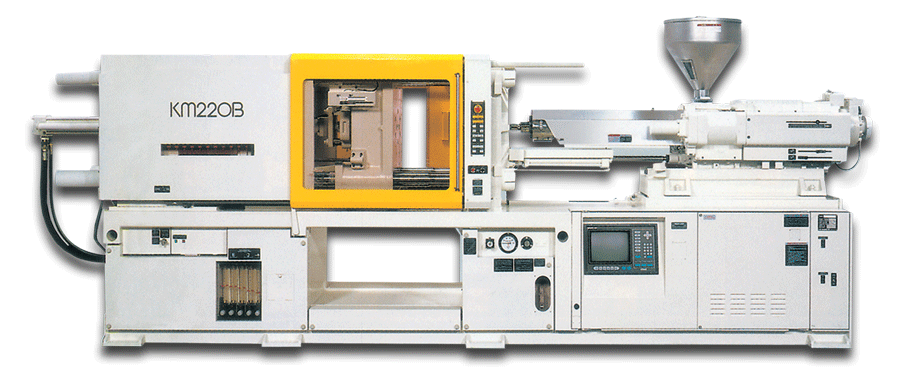

kawaguchi

KM – 140 Ton Capacity

KX – 100 Ton Capacity

yizumi

SK III – 160 Ton

SK III – 220 Ton

SK III – 450 Ton

Sumo Windsor

300 Ton

450 Ton

Lakshmi Moulds & Dies

Quality Standards & Certifications

We adhere to the highest industry standards to maintain superior quality. Our infrastructure supports:

- ISO-certified quality management systems

- Stringent quality control at every stage

- Advanced testing and inspection tools to ensure precision and durability

Lakshmi Moulds & Dies

Quality Standards & Certifications

We adhere to the highest industry standards to maintain superior quality. Our infrastructure supports:

- ISO-certified quality management systems

- Stringent quality control at every stage

- Advanced testing and inspection tools to ensure precision and durability

Lakshmi Moulds & Dies

Sustainability & Safety

We are committed to environmentally responsible manufacturing and workplace safety:

- Energy-efficient production systems

- Waste management and recycling processes

- Robust safety protocols and employee training programs

Lakshmi Moulds & Dies

Power & Connectivity

Our facilities are powered with backup solutions to ensure uninterrupted operations. We maintain high-speed connectivity for seamless design, development, and client communication.

Lakshmi Moulds & Dies

Power & Connectivity

Our facilities are powered with backup solutions to ensure uninterrupted operations. We maintain high-speed connectivity for seamless design, development, and client communication.

Lakshmi Moulds & Dies

Logistics & Supply Chain

With a well-organized supply chain, we ensure:

- Just-in-time delivery to OEMs and Tier 1 customers

- Strong vendor partnerships for material procurement

- Efficient warehousing and dispatch systems

Lakshmi Moulds & Dies

Request Our Service

Lakshmi Moulds & Dies

- +91 98437 75434

- info@lakshmimoulds.com

- Unit 1: No 2/16B, Motham Agraharam, ESI Ring Road, Hosur, Krishnagiri, Tamilnadu - 635126.

- Unit II: Plot No62. 733/1A, Dhinnur, Barandhur, S.mudhuganapalli, Denkanikottai, Krishnagiri, Tamilnadu - 635110.